When you think of WP suspension, off-road racing and KTM may come to mind. KTM no longer owns WP Suspension, however, and WP Suspension has expanded into the road market. Indeed, the Moto2 World champion Johann Zarco dominated the series this year on WP suspension. Zarco clinched the title early, and has a chance to set records for the most points ever earned by a Moto2 rider in a single season, and the most podium finishes. Don’t be surprised if you see WP Suspension on a MotoGP bike within the next few years.

WP is already providing OEM suspension for KTM street bikes, including MD’s 2014 Bike of the Year, the KTM 1190 Adventure.

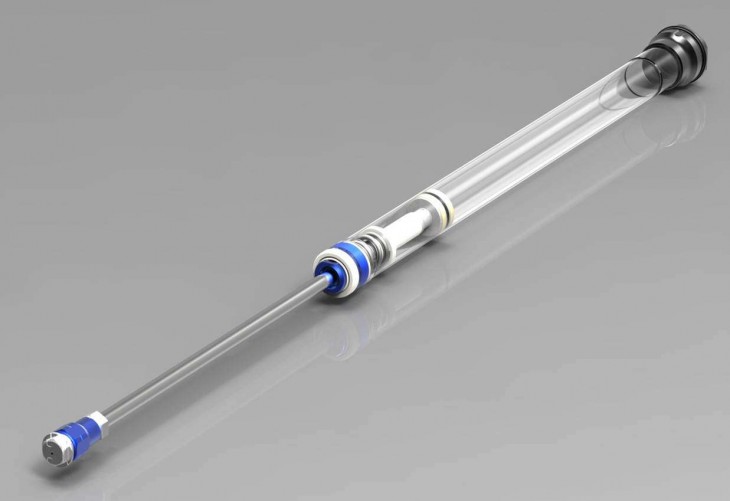

Last evening in Temecula, California, not far from the Murietta headquarters of WP Suspension North America, WP brought together a group of journalists to announce its 2016 products. In addition to updates to its existing line of off-road and on-road suspension products, including forks incorporating WP’s unique Cone Valve technology, WP unveiled a new off-road air fork, appropriately called the AER 48. In addition to dropping 3 pounds of weight from the standard steel-spring fork, the AER 48 allows the rider to customize the spring rate with the use of an air pump. Air suspension is arguably the future, even for road bikes, and WP indicates the AER 48 is just the beginning of its development of this technology.

If you are interested in the technical details, or a look at WP’s full catalog of suspension products, visit WP’s website.

See more of MD’s great photography:

Love the ease of preload setup and light weight on my mountain bike’s air fork, but the ramping up of the spring rate on extreme travel is a problem. Fork seals also blow out every year or two with regular trail riding. I wonder how WP can get around the progressive spring rate, if at all?

Q: I wonder how WP can get around the progressive spring rate, if at all?

A: valving I’d imagine.

albeit compressible, air’s a fluid much like fork oil. hydraulic fluid gives similar progressive curves, but that’s where shim stacks and linkages come in.

Good to see WP moving ahead with gas based suspension. I recently contacted Fournales and found their product information and response from the factory and their product representatives both chaotic and not user-friendly for English speaking contact.

It’s not hard to see why Fournales is effectively a non participant in the motorcycle industry given their management approach

It’s good to see a genuine innovation coming from a class where the chassis is the only variable.

I’m slightly disappointed that we haven’t seen any hub centred steering bikes or similar, though. With the engine a constant, it’d be the best place to truely develop and compare technolgies. Elf Honda, anyone?

Spring curve is different between coil and air.

This us a cost cutting effort. Steel springs require high quality steel. Air is cheep.one issue with air is the effectively rapid rise rate that overpowers the damper.

Its cost AND weight cutting effort. Both are things that the industry should strive for.

Every production “coil spring” telescopic fork is actually a hybrid coil spring/air system, as the air trapped in the fork will act as spring when the fork is pushed. They all also have effective rising rate.

Btw. the AER 48 is original equipment on 2016 European spec motocross bikes from KTM.

re: “This (is) a cost cutting effort. Steel springs require high quality steel.”

sure does smell like it…?

I saw where Suzuki moved to an air fork for the RM-Z450. The only air suspension I’ve ever had experience with (besides automobiles of course) is the Fox air shock on my mountain bike. It is over 15 years old now, never been serviced and still works perfectly. If it can be made to work as well for motorcycles, I say bring it.

The 1976 YZ’s had air (only) forks. They are pretty easy to spot when you see them on Craigslist (the front tire is bottomed out against the front fender). The fad lasted exactly one year.

I have not heard good reviews about the new RM’s air forks.

I also have a Fox fork on my 29’er that works great and never leaks a bit of pressure. I check it once a year whether it needs it or not.

we had gas /air pressurized forks and shocks on our Yamaha MX bikes in the mid 70’s and on Honda Goldwing and CB900C street bikes in the 80’s. What makes this new or better?

Mastery of air-spring chamber sizes and damping curves. Reliable seals too. The old problem with air springs that took some years to work out on MTB’s was making air spring chambers large enough in volume so that could achieve a flat enough spring curve. They were CRAZY progressive in the early days.

I question how they’ll deal with temperature in the race environment but the Suzuki and Kawasaki MX teams are on air forks so they must have figured something out. I suppose that problems has always existed for oil too.

“I question how they’ll deal with temperature in the race environment”

Nitrogen?

Nitrogen is affected by temperature just like any other gas.

As long as it’s pure/free of moisture. It’s used because it’s a cheap option when you are concerned about changing temperatures affecting pressure.

True, a significant amount of moisture will cause irregularities in pressure, but it is my understanding that the amount of moisture in air is not material enough to have a noticeable effect. The fact that nitrogen is inert and lacks moisture (and oxygen) make it useful in applications where unwanted chemical reactions such as oxidation can occur, but I think the mountain bike scene has proven that to be a non-issue. I’m just regurgitating things I’ve read over the years, so I could be completely wrong here.

That said, I suspect you re probably right: race teams will use nitrogen… just in case.

I have a small nitrogen tank in my garage for recharging shocks but I did experiment with plain old air (70% nitrogen) in my dirt bike shock for a season. There was no discernible difference in performance or shock temperature. I have heard that race teams inflate tires with nitrogen but the volume is much bigger there and a slight pressure change can have a bigger effect on performance.

Pure argon or nitrogen gas is unaffected by temp. changes and is used in refrigeration/AC for that reason. But keeping it pure on a MC is easier said than done.

definitely pure N2. offsetting the expansion due to heat gain was the only way the AMA/Dunlop was able to run the high banks of Daytona without tyre explosions…

and they STILL had tyre explosions.

All gases are affected by temperature. I imagine they use argon and nitrogen in the HVAC world for the same reason those gases get used in many other applications: they are inert and don’t carry moisture.

Can’t get away from the ideal gas law (https://en.wikipedia.org/wiki/Ideal_gas_law).

I’d say you stay away from air because a slight amount of moisture in the air will expand crazily above 100C.

Well done WHITE POWER!

Losing 6 lbs for racing purposes is pretty useful though. Probably not the best choice for a touring bike.

I’ve had low pressure air shocks(Progressive) and to be honest hardly ever had to check them for pressure. I got them ’cause I couldn’t get spring shocks to handle the weight loads I had riding 2up+. In this application heat causing + air press. was good for what I was using them for. But on a bumpy MX, SX course…………that’s a whole different can of worms! I have gas charged shocks on some of my street bikes and so far they are good. But if & when their seals leak………I’ll be in a world of hurt.

pv=nrt….. gas is gas… The effects on gas pressure with regards to temperature does not vary with the make up of the gas (unless the gas is subjected to a change of state).

P=pressue in atmospheres, V=volume, n=amount of gas in moles, r=gas constant 0.0821, t=temperature in kelvin. Dry gas is a plus (again about the issue of change of state…. if the moisture were to condense the ideal gas equation gets thrown out).

It’s a lot easier to keep a steel spring inside a fork than molecules of air/gases under varying load and pressure, be no fun to loose your front spring off road somewhere on an Adventure bike. French made air Fournales shocks are still around for the H.D.’s etc, but never really became main stream. Still, we now see more of air suspension on M.B. cars and Range Rovers so maybe WP is onto something, at least for closed circuit racing.

Yes, but all things change overtime due to better technology and materials and time.

Don’t doubt till you crashed it! 😜

It’s been over hundred years since pneumatic tires were invented.

The issue of escaping air hasn’t been solved yet.

We still need to periodically check air pressure.

Some things can’t be changed.

Air will slowly leak from this fork.

The promise of a lifetime of zero maintenance is not being implied here. We check our tire pressure, we change out motor oil, coolant, clean our filters and oil our chains.

FWIW, leak-down with air suspension is amazingly low. The only place air can escape is around the seals and the valve. tiny areas compared to a tire (the rest of the chamber is metal). I have air sprung suspension on my MTB, I re-pressurize it maybe twice per year and find it only a couple psi lower than where I had set it 6 months before.

Dave said: “I re-pressurize it maybe twice per year and find it only a couple psi lower than where I had set it 6 months before.”

Didn’t I say “slowly”?

Back in the 80’s I had a semi-air-sprung VT250F.

Re-pressuring was needed only once a year when it was new.

More frequent as it got older.

I’m sure progress has been made but, hey a leak is a leak.

You do realize that on a conventional spring fork you should open the bleed screws to release air build-up before every ride (every moto/session in MX)?

Any quality rear shock (or front shock on BMWs) is gas charged. Do you see many blown-out shocks on the roads?

But air changes pressure with temp. changes. I would think argon or nitrogen gases would be better for consistent shock results.