A new small-volume motorcycle manufacturer in the UK held a press event last week to introduce new models built around a 750 cc triple (derived from stroking a Triumph 675, as we understand it). These are intended to be extremely high performance motorcycles with adjustable chassis suitable for racing or spirited street use.

There are sport models and naked models planned and they are not inexpensive. Using current exchange rates, the cheapest model starts at roughly $56,000 U.S. ranging to roughly $85,000 U.S.

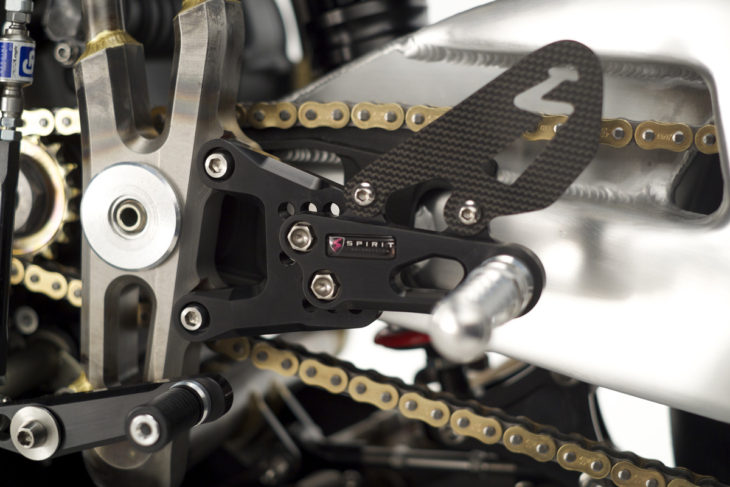

These are largely hand-built, limited production motorcycles, and the claimed power-to-weight ratios are very impressive. In various states of tune, the 750 cc triple is claimed to produce from 156 horsepower to 180 horsepower. The company is claiming dry weights well below 350 pounds. Have a look at the Spirit website, as well as the following video for more information.

See more of MD’s great photography:

Needs knobby tires and a beak

Are small volume manufacturers in Britain exempt from having to conform to Euro emission regs? The exhaust system on this (and that Norton you featured a few days ago) looks way too nice to be politically correct.

At least these guys are doing it right. The bike is beautiful, and 180 hp and 350 lbs. dry weight, holy crap. That’s insane for a bike not limited to the track. “Spirited street use”, if you owned one of these I’d suppose there would be no other possible use.

Looks like a sweet bike. Only concern would be the brazed frame. For example, in aviation brazing is not allowed in the primary control system when joining tubing. Only welding is acceptable as it is a more reliable. When building a motorcycle that will experience harsh duty,exceed 200 mph and cost $85,000 why would you use brazing? TIG welding would be the obvious choice as it offers more strength and weighs less to boot! TIG does require a skilled operator and more expensive equipment to produce a weld but is light years ahead of brazing when it comes to high performance applications.

I don’t know a whole lot about brazing so correct me if I’m wrong, but from videos I’ve seen, this has the appearance of TIG brazing, using aluminum bronze filler. I watched some chrome-moly tubing brazed this way, and when they tested it, the tube bent in half before the joint was compromised, so it seems to be pretty strong.

Still don’t know why this would be preferable to welding, though…

As a certified welder (30yrs experience) with brazing experience (I was taught by really old guys in blue glasses when I was an apprentice) I can confirm brazing can definately be stronger than welding. Although brazing filler material has a lower tensile strength than the chromoly steel it is joining, a properly prepared lug with a large surface area can create a stronger joint than a TIG butt weld. The brazed joint also has a small amount of cushion due to the lower tensile strength allowing the joint to absorb sudden shock better. The lower temperatures involved also eliminates the heat affected zone which is the area right beside the weld where most joints break. The lugs weigh more than a well prepared butt joint so in this case I suspect the designer is going for a unique look. It caught my eye!

Thanks for the info!

Grover,

I think brazing is used for uniform repeatability in the manufacturing process in a hand built product at least.

Traditional welding has an inherent risk of deformation.

That is , unless you have super precise cuts in th tubing welding has a tendency to move the parts ( tubes out of alignment . As Norm has Indicated, because the base Metal is melted in the process. .

Not so with brazing..

Thats’s what I’ve read anyway. I

As I’ve always understood it, welding requires greater heat than brazing and therefore can alter the tensile properties of the tubing more. Not so?

That makes sense.

In addition, I suppose it might be easier to repair a damaged frame as well, because you could sweat out the bad section of tubing and just braze in a new piece in its place…

Here’s a great article on the Ducati Motogp Desmosedici and the reasons that they tried the switch from the trellis to the carbon fiber frame.

( The variability from one Trellis frame to the next could be as much as 15% difference in chassis flex ! )

https://www.motomatters.com/analysis/2011/08/08/the_trouble_with_the_ducati_desmosedici_.html

In aerospace, welding aluminum is frowned upon also since it significantly reduces the strength of the aluminum in the heat affected area. That doesn’t seem to stop manufacturers from welding aluminum motorcycle frames together either. A good engineer will accommodate the lower strength areas by reducing loads in those joints (add more material/weight or more connections to increase the strength).

Here, brazing is being used as a design element. I imagine every effort was made to make sure it is appropriately engineered.

Beautiful welds…beautiful bike. I wish them the best.

Just what I was hoping to see on MD this morning. Another ’boutique’ bike that I could never afford. Blahh

So what it seems that we have here is a regular production street bike engine that has been breathed on and placed in a chassis with an expensive set of wheels. Other than the wheels. What is there about the 100 pounds of saved weight that the OEMs cannot seem to ever produce? How embarrassed would they have to get about their wheels to claim that the wheels are most of the savings? Aren’t you lucky to save ten pounds with a set of carbon wheels? So the other 90 or so comes from the lack of ridiculously heavy parts doesn’t it? That is a steel frame held together with brass after all.

“new models built around a 750 cc triple (derived from stroking a Triumph 675, as we understand it)”

I stroked a 675 once, but it didn’t look anything like this! Plus my hand cramped up pretty hard.

Really nice looking bike, wish I had a big bank account, and a bigger garage!

Brazed frame! Looks like raw tubing as well – possibly titanium?

Chromoly steel, brazed with brass. They must’ve clear coated it post process. It’d rust quickly without.

From the front it looks alive. Kinda like a friendly animated Pixar character . Frame looks a bit ” spindly too. Not exactly large diameter tubing at first glance.

Tony Foale used to build frames by brazing rather than welding so I’ve seen it before but never in a high end performance package.

Fit and finish look very nice.

re: “Brazed frame!”

re: “Tony Foale used to build frames by brazing rather than welding so I’ve seen it before”

Azi, Joe careful. i don’t think that’s pure brazing…? so much as it’s braze WELDING. I only say this cause I see overlapping puddles (similar to the arc used on the ally rear fork). though the base metal doesn’t melt like in traditional welding, this is made by deposition and not capillary action like we know from low temp soldering. it then has to be mechanically worked as a secondary step to clean it up and create the smooth fillet.

i mention this cause I fondly remember back in the heyday of BMX a bike the original Schwinn company put out in 1980 called the Sting (yes the successor to the famed Stingray of the 70’s). it’s selling point was a brazed headstock of ovalized 4130 and rear dropouts. if you have one today, it’s VERY collectible, talking like THOUSANDS of dollars collectible, and it was NOT a cheap bike either, back in 1980 it was $500 bucks.

http://bmxmuseum.com/image/dscn2193_copy0_blowup.jpg

http://farm6.staticflickr.com/5030/5644652659_3b2227cee0_b.jpg

http://images.singletracks.com/blog/wp-content/uploads/2011/09/construction01-533×400.jpg

Good points Norm G, I suspect there is more than meets the eye when it comes to this bike’s bespoke frame. I can’t find any information on the frame material on their website (perhaps I’m just not looking in the right place) but the welding/brazing/whatever technique will likely be dictated by the tubing material.

Yes frame nerdery is a much bigger deal in the cycling world, with much more debate over steel alloys, carbon fibre weaves, titanium, and alu alloys happening there than moto land. Imagine if this motorcycle frame had lugs – the hipsters would go nuts.

I’m not sure how much photoshop is on the last photo but it looks remarkably simple and clean.

I guess this as well as many other expensive boutique brands and very expensive models from established “normal” brands means recession is over.

Maybe one day we will go back to those days of new better lighter model every 2-3 years.

Sweet looking bike! Nice simple lines on the bodywork and the steel frame is (as my gf says) tits.

I’ve been looking at my bike all wrong!

“In various states of tune, the 750 cc triple is claimed to produce from 156 horsepower to 180 horsepower. The company is claiming dry weights well below 350 pounds.”

The motorcycling equivalent of vaporware.

You’re a real “glass is half empty” kinda guy, aren’t you…

There has to be some actual water available to get it to even half full empty.

a Bri’ish Bimota.

They both look like very hi quality machines and the spec is awsome. Not sure about the Milo can exhaust on the faired bike though, especially when the exhaust on the naked bike looks like a work of art.

Zowie! 100 lbs less than a new open class SBK, down only 20hp or so. Um, yeah, I’d take this thing. How strange and potentially embarrassing to be at a track day on your well tuned Yamaha R1, and be passed mid corner by this little Spirit bugger.

Given a decent amount of skill, I don’t know if a particular rider would be able to lap any faster on this bike than he would on a well-tuned R1… But it sure would be nice to be in the position to find out.

Wow, a nice counterpoint to the seizure inducing, b’farkled and faceted surfaces Japan has been treating us to lately. “transformers…more than meets the eye…”

Also… wow… I’d be interested for sure if 1. I had the $$ and 2. I knew that the whole package worked together as well as it looks. 🙂

I hope they at least to kits for motor upgrades… I love the rev sound of a triple… nothing like it!!!

Well if Triumph isn’t going to up-cc their 675 (which I own and love by the way), then I guess someone else will.

I mean… riding the 675 is so awesome. My Street Triple R goes and handles like crazy and with a Penske, pipe / PCV and adjusted suspension… you do truly wonder; why do I need anything else?

Then you ride a 1k / V4 Tuono and go HS!!! this feels good. Not near as sweet as the triumph in many areas… but it sure puts the smile on your face when you TWIST the grip.

That said, pushing my Street Triple is something I probably couldn’t do as well on the Tuono and did I mention how SWEET that Triumph is… Incredible!!!

I understand Craig.

Because MOTORCYCLES! Yay!

^ This.

why? to be different.

sure like the profile in the last pic. i wish, tho, that pics included street-legal bikes with mirrors and turn indicators, etc. jmnsho 😉

No mirrors but the license plate holder and turn signals are there. Look at the LED strips on either side of the fairing and the tail section.

It may have a rear-view camera that shows the image on the dash…?

why?

why not…its motorcycle innovation…i cant afford one….cant afford a Bugatti either..somebody can..good for them…still cool..love it.